Sementasyon işlemi, yüzey sertliği aşınma dayanımı ve sürekli dayanımı iyileştirici özelliğe sahip olmakla birlikte, parça çekirdek bölge dayanımı ve sünekliğini de iyileştirir. Bu sayede büyük yüklerin taşınması, darbe tarzındaki yüklerin karşılanması sağlanır.

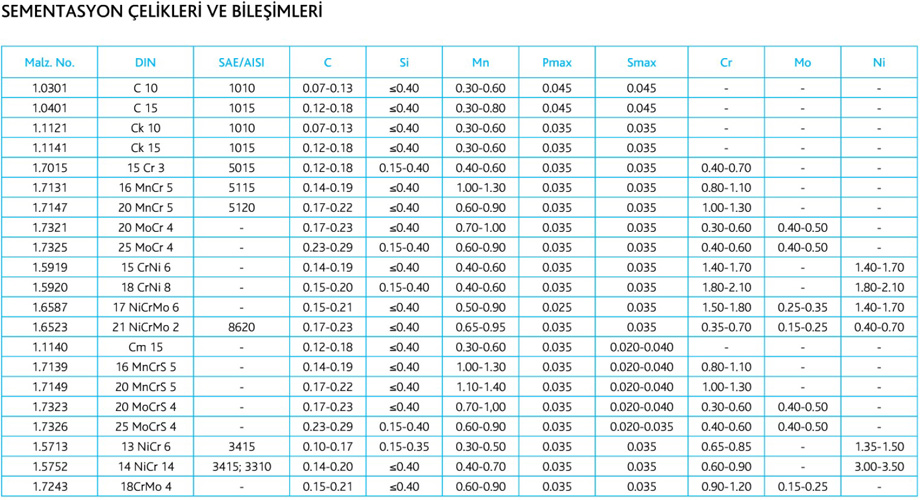

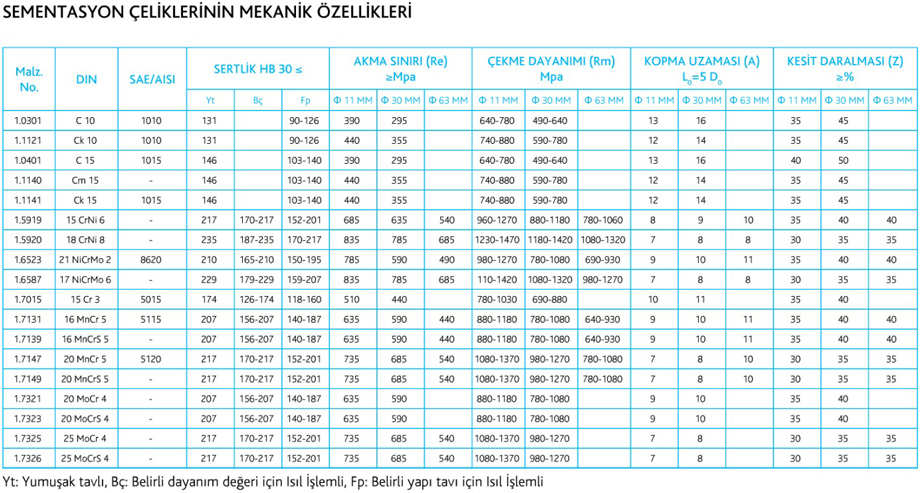

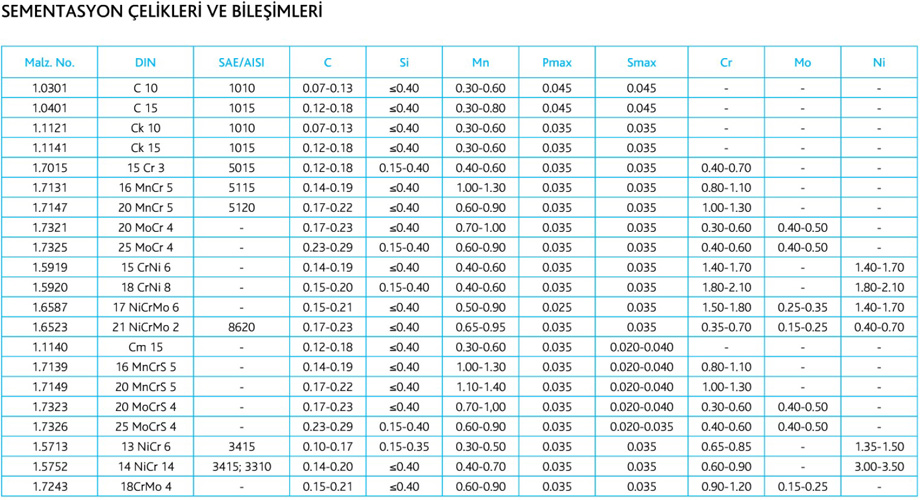

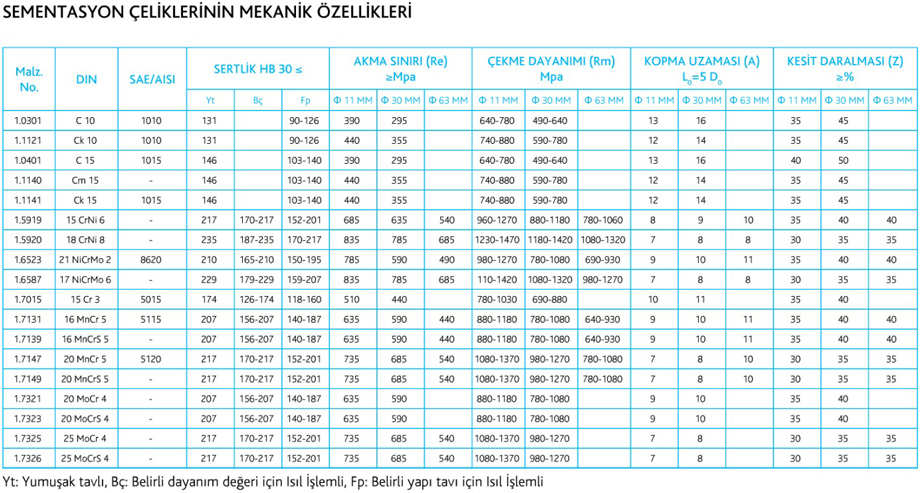

Sementasyon malzemeleri karbon oranı genelde %0,10-0,20 arasındadır, bazı çeşitlerde %0,25′e kadar çıkabilir. Alaşımlı veya alaşımsız olarak üretilebilirler.

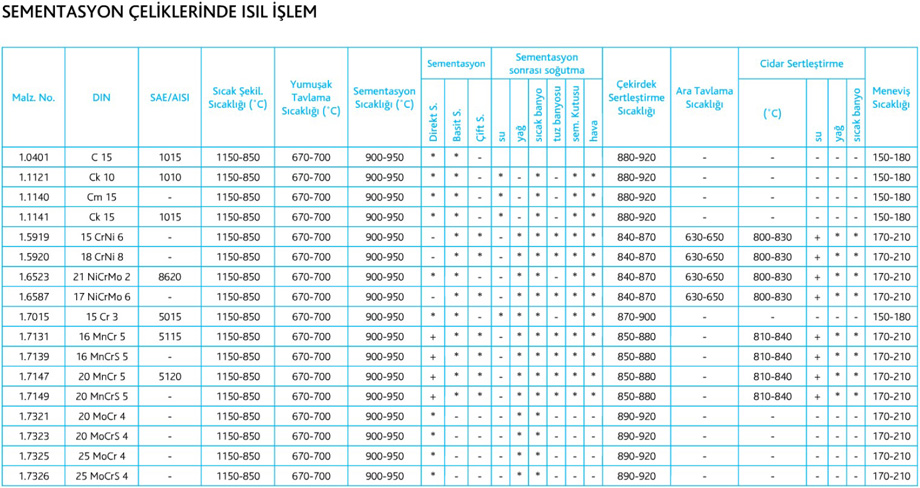

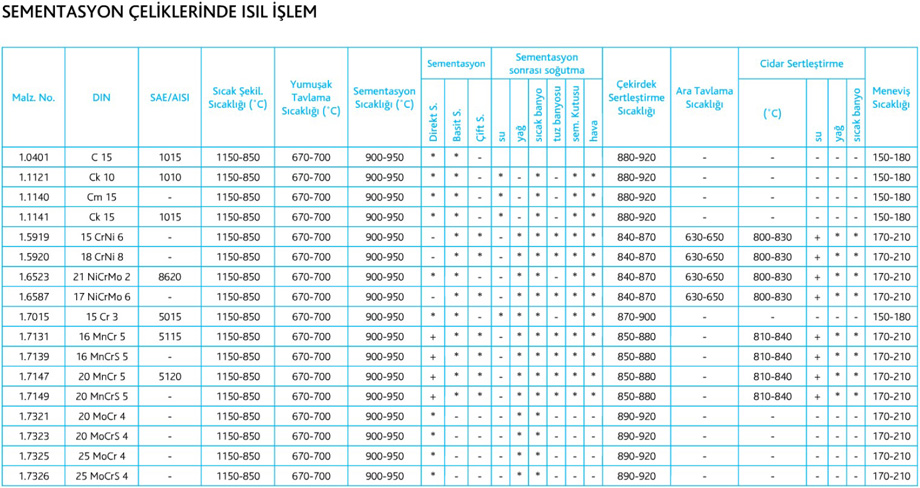

Sementasyon çelikleri, sementasyon işleminden sonra değişik şekillerde ısıl işleme tabi tutulabilirler. Sementasyon işleminden sonra çekirdek bölgedeki karbon miktarı %0,10- 0,20 değerlerinde kalırken, yüzey bölgede karbon miktarı %0,80′e kadar yükselir. Bu durumda yapılacak ısıl işlem sıcaklığının seçimi, parça yapısının her yerinde değişen karbon miktarı nedeniyle zorlaşır. Çekirdek bölge baz alınarak seçilecek sıcaklık parça cidar bölgesinde tane irileşmesine, parça cidar bölgesi baz alınarak seçilecek sıcaklık, çekirdek bölgenin yeterince sertleşememesine yol açar. Bu sebeple uygulanabilecek en kolay yöntem sementasyon sıcaklığından direkt sertleştirmedir. Bu yöntem sadece tuz banyosu ve gaz sementasyonundan sonra uygulanabilir. Yöntem ince taneli çelikler için daha uygundur.

Sementasyon çeliklerinde karbon miktarının yükselmesiyle ve ilave edilmiş alaşım elementleriyle, çekirdek bölge dayanımı artırılabilir. Ancak en verimli sonuca, sementasyon sonrası çekirdek sertleştirmesi ile ulaşılabilir. Bu yönteme çift sertleştirme adı verilir. Çekirdek bölge uygun sertleştirme sıcaklığından ani soğutulan parça, ara tavlama işlemine tabi tutulur ve ardından cidar bölge için uygun sertleştirme sıcaklığından ani soğutularak cidar bölgenin sertliği sağlanır. Sementasyon çeliklerinin kaynak kabiliyetleri iyidir.

Alaşımlı çeliklerde kaynaktan sonra tavlama gerekir. Talaşlı işlenebilirlik en iyi, normal tavlanmış veya kaba taneli yapıya sahip malzeme ile sağlanır. Yumuşatma yapılmış malzeme kötü yüzey kalitesi verdiği için tercih edilmez.