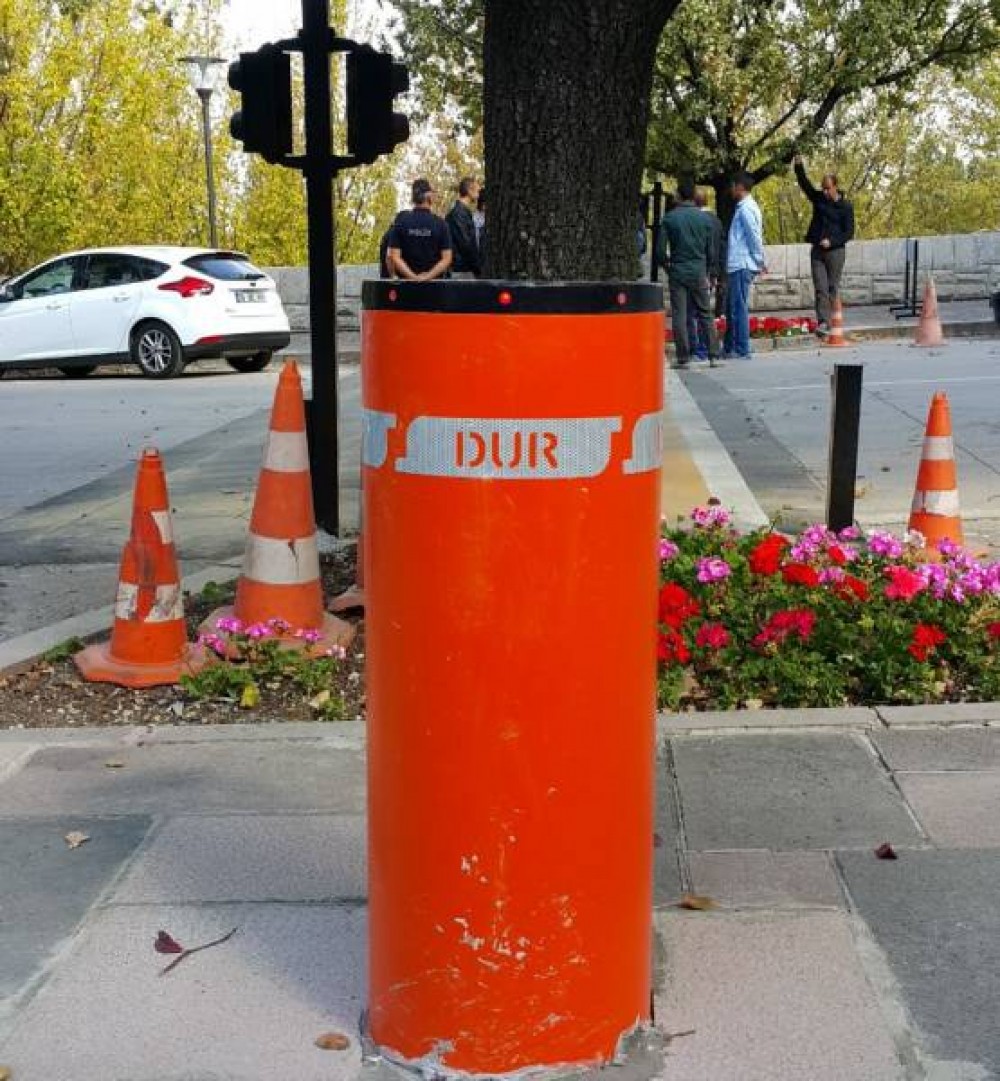

Çarpma Testli Mantar Bariyer Sistemleri (K12/PAS68), iki farklı şekilde imal edilebilirler: Sabit sistemler ve Hidrolik basınçla çalışan sistemler. Hidrolik basınçla çalışan mantar bariyerler için Hidrolik mantar bariyer ürünümüzde bulunan temel bilgiler geçerlidir. Bu ürün modelinin diğer mantar bariyerlerden farkı çarpma testi sertifikalarına sahip olmasıdır. Madoors yüksek güvenlikli anti terör mantar bariyer sistemleri K12 ve PAS68 çarpma testine sahiptir. K12 crash test raporu Amerika standartı, PAS68 crash test raporu Avrupa normudur ancak ikisi de aynı özelliklere haizdir. Bu testlerde hedef test edilen mantar bariyerin 80 km saat hızla gelen 7500 kg. ağırlığında bir aracı durdurabilecek kapasitede olduğunu belgelemektir. Sistemlerimiz yoğun kullanıma uygundur. Hidrolik sistemin gelişmiş yapısı ve stabilitesi sayesinde yıllarca herhangi bir bakıma ihtiyaç duymadan ve sorunsuz bir şekilde çalışırlar. Bu sebeple oldukça çok tercih edilen bir bariyer sistemidir. Bununla birlikte test raporları ile çarpmaya karşı oldukça mukavim ve sağlam oldukları belgelenmiştir. Söz konusu mantar bariyer sistemlerimiz araç çarpmalarında çalışmaya devam edererek olası güvenlik zaafiyetlerinin önüne geçerler. Madoors olarak Türkiye'de ilk mantar bariyer üretimi yapan, bu ürünün isim hakkını elinde bulunduran firma olduğumuzu da özellikle belirtmemiz gerekir. Genel Özellikleri Çarpma testli mantar bariyer sistemlerimiz K12/PAS68 N3 çarpma testi ile 7500 kg. lık bir aracı 80 km/saat hızla çarpmaya, saldırıya karşı bloke eder. Söz konusu sertifikalar Fransa'da konuşlu bulunan resmi ve bağımsız test kuruluşu Transpolis firmasından 2015 yılında alınmıştır. Sertifikalarımız sayfasına bu belgelerin kapaklarına ulaşabilirsiniz. Güvenlik nedeniyle tüm içeriğini paylaşamadığımız bu sertifikaları fiyat teklifi ile birlikte talep ederseniz, size ulaştırmaktan memnuniyet duyarız. Hidrolik mantar bariyer sistemleri 3 parça imal edilirler. Dış gövde, iç kızaklı gövde ve hareketli kısım. Dış gövde yere gömülen kısımdır. İç kızaklı gövde hareketli kısmın sorunsuz olarak inip kalkmasını sağlayan parçadır. Hareketli parça ise yükselerek esas bariyer görevini icra eden kısımdır. K12/PAS 68 çarpma testli hidrolik mantar bariyerlerimiz acil durumda, acil start butonu ile 1-2 sn de komple yükselir ve iner. Araçlar ve bomba yüklü kamyonlar ile yapılabilecek saldırıları bu sayede anında bloke eder. Hidrolik yapılı bariyer sistemlerimizde iniş ve kalkış hızı hidrolik vanalar sayesinde ayarlanabilir. Bu süre en fazla (maksimum) 3-5 saniyedir. İstenirse ekstra azot tüpü uygulaması ile bariyer 1 saniyede inip kalkabilir. Opsiyonel olan bu özellik yüksek güvenlik gerektiren girişlerde şüpheli araç ile yapılan bomba yüklü terör saldırılarını anında bloke etmede kullanılır. Bu nedenle çarpma testli ürünlerimizde tercih edilebilmektedir. Çarpma testli bariyerlerimiz yerden 60 cm, 70 cm, 80 cm ve 100 cm yüksekliklerde imal edilebilirler. İhtiyaca göre farklı çalışmalar da yapılabilir. Tek aks başına düşen yük dayanımı 40 ton'dur. Çelik hareketli bariyer gövdesi 10 mm. et kalınlığında imal edilir. Hareketli ana gövde paslanmaz çelik cr-ni veya çelik çekme dikişsiz borudan imal edillebilir. Bu boru sıcak daldırma galvaniz kaplanıp yıllarca paslanmaz çelik bariyer gibi tertemiz bir şekilde kalır. İstenirse paslanmaz (Cr-ni 304) krom nikel çelikten imal edilebilmektedir. Fotosel koruma güvenlik sensörü bariyer eksenin önünde ve arkasında 1'er metre mesafede olmak üzere 2 set şeklinde teslim edilir. Uzaktan kumanda alıcı kart 2 kanaldır. Tüm hidrolik mantar bariyer sistemlerimizde loop dedektör uygulaması vardır. Bariyer sistemlerimiz plaka okuma/tanıma ve RFID sistemi uyumludur. Sistemin tamamı kuru kontak bilgileri ile çalışır. Dubası üzerinde power led ışıklar mevcuttur. Hidrolik ünite IP 65 standartına sahiptir ve ayrı bir muhafaza kutusu veya bariyer gövdesi içinde imal edilebilir. Bariyer sistemi için farklı renk seçenekleri mevcuttur. Boşa geçirme vanası sayesinde arıza durumunda veya elektrik kesintisinde bariyer manuel olarak açık konuma alınabilir ve böylece geçişe olanak verir. Hidrolik mantar bariyer sistemlerimiz 2 yıl garantimiz altındadır. 10 yıl yedek parça bulundurma garantisi vardır. Arızalanma riski mevcut değildir denilebilir. Düşük bir ihtimal de olsa arıza durumunda iç hazne yere monte edilen dış hazneden kızaklı olarak çekilerek yukarı alınır ve bariyerin kullanımına devam edilebilir. Ayrıca bariyerin bakımı da bu şekilde hızlı ve kolayca yapılır. Arıza durumunda PLC kontrol ünitesi sayesinde uzaktan bağlantı ile belli noktaya arıza bilgisi verir. Basit arıza yönergelerini ve sorun giderilebilecek basit arızaları ( Fazın biri gelmiyor, sigorta atık, faz ters, motor aşırı akım çekiyor vb.) kullanıcıya plc dijital ekranından bildirir. Buton için analog veya dijital seçenekleri vardır. Dijital butondan bariyer panosuna gitmeden tüm ayarlar yapılabilir. Hidrolik güç ile çalıştığı için bu tip mantar bariyerler yaz kış ortam şartı gözetmeksizin çalışmaya devam eder. Kışın üzerinde buz oluşması durumunda buzu kırarak dışarı çıkar ve çalışmaya devam eder. Yazın çok sıcak bölge ve ülkelerde yağ soğutucu kit sayesinde engelsiz çalışır. Çelik baba bariyerlerimiz sabit olup zemine gömülerek montaj edilirler, zemin üstünde kalan kısmın yarısı kadar zemine beton ankraj demirleri ile montaj edilir. Buradaki amaç anti-terör bariyeri olan bu bariyer sistemimizin bomba yüklü araç ile yapılması planlanan saldırıları bloke etmesidir. Ağır tonajlı araçların sürat ile kazındıkları kinetik enerjiyi bu bariyer sistemlerimiz ile girişlerinizde sönümleyebilirsiniz. Bunu sağlamak içinde K12/PAS68 çarpışma testli çelik baba bariyerlerimizi zemine iyi bir ankaraj sistemi ile betonlamaktayız. Sabit mantar bariyer dubalarımız çarpma sonucu kesinlikle hasar görmez , Bu ürünlerimiz anti-terör bariyeridir. Hareketli mantar bariyerlerin sağına , soluna veya kapatılması gereken boş bölgelere nizamiye girişlerinde boşluk bırakmamak için kullanılır. Sabit mantar babalarımız Çarpma test belgesi sahibidir. Yurtdışı bağımsız test kuruluşu onaylıdır. Üst kapak çıkabilir istenirse içine beton dökülür.Üst aydınlatmalar ile gece net bir şekilde gözükür.Paslanmaz çelik cr - ni 304 , çelik üstü sıcak daldırma galvaniz kaplama , kumlama sonrası istenilen ral kodunda elektro-statik toz boya ile imal edilirler. Kullanım Alanları K12/PAS68 çarpışma testli mantar bariyer sistemlerimiz elçiliklerin çevre güvenliklerinin sağlanması amaçlı aralarında 100-120 cm boşluk bırakılarak çevre alana sıra ile dizilerek montaj edilmesi tavsite edilmektedir. Bu sayede çevre duvarlarında araç ile yapılacak saldırıları bloke etme imkanı sunar. Hidrolik mantar bariyer sistemleri araç girişinin engellenmesi ihtiyacının bulunduğu hemen her yerde kullanılabildiği gibi aşağıdaki alanlarda özellikle tercih edilmektedir; Otopark girişlerinde, Özel garaj girişlerin, Askeri ve Emniyet güçlerimizin nizamiyelerinde , Devlet kurum ve kuruluşlarında, Araç girişinin engellenmek istendiği turistik sokak ve caddelerde...