EN IEC 60332-3 standardı baz alınarak Avrupa Yapı Malzemeleri (CPR) direktifi 305/2011 kapsamında EN 50399 standardı hazırlanmıştır. EN 50399 standardı, düşey alev yayılma deney düzeneğinde, ısı ve duman yoğunluğu ölçümlerinin entegrasyonunu düzenlemektedir. Bu standard kapsamında deneye tâbi tutulan kablolar, yanma dayanımlarına göre sınıflandırılabilmektedir.

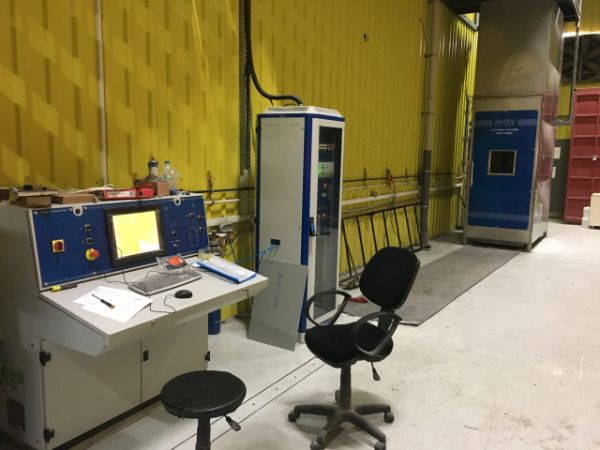

Gerek yanma dayanımı deney cihazları, gerekse kablo test cihazları tasarım ve üretiminde Türkiye’de öncü marka olan MATEŞ ELEKTRONİK, EN 50399 Test Cihazı üretimini gerçekleştirmektedir.

MATEŞ ELEKTRONİK EN50399 Deney Cihazı 5 ana bölümden oluşmaktadır;

- Deney Kabini:

EN IEC 60332-3 standardında tarif edilen 100x200x400±10cm deney kabini kullanılmaktadır. İçi ve dışı AISI 304 1,5mm paslanmaz çelik olan deney kabininde ara yalıtım malzemesi olarak standard tarifine uygun 0,7 W/m²·K katsayılı taş yünü kullanılmaktadır. Temiz hava girişi için, standard tarifine uygun olarak 1060m3/h değerine ayarlanmış hava akış fanı kullanılmaktadır. Bek ve venturiler, standartta istenen üreticilerden tedarik edilmektedir. Farklı merdiven genişlikleri için iki adet bek sağlanmaktadır. Bek konumları çok kolay ayarlanabilecek biçimde tasarlanmıştır. Geniş ve dar olmak üzere iki adet paslanmaz çelik merdiven kabin ile birlikte sağlanmaktadır. Deney kabini üzerinde, numunelerinin kolay yerleştirilmesi için vinç bulunmaktadır. Söndürme için kabin içi CO2 tesisatı ve pnömatik kapanabilir üst kapak mevcuttur.

- Duman Tahliye Sistemi

Standard tarifine uygun, deney kabini üzeri davlumbazı içerir. Operatör tercihine uygun olarak deney gazının ölçüm borusuna veya ölçüm borusundan bağımsız olarak direkt dışarı yönlendirilmesini sağlayan kontrol sistemini içerir. Her iki çıkış noktasında da fan mevcuttur. Ölçüm borusuna bağlı fan inverter kontrollü olup, fan hızı, deney cihazı tarafından gerçek zamanlı olarak kontrol edilmektedir.

- Ölçüm Borusu:

Standard tarifine uygun olarak imal edilen içi paslanmaz çelik olarak imâl edilen ölçüm borusu, ısı ölçümü için gaz/basınç/sıcaklık analiz problarını ve duman yoğunluğu analizi için gerekli ışık düzeneğini içermektedir. Işık düzeneği kalibrasyonu için standardın belirttiği 1 set mercek sağlanmaktadır.

- Gaz Analiz Ünitesi:

Cihaz kapsamında kullanılan gaz analiz ünitesi, ölçüm borusundan örneklenen deney gazının Oksijen ve Karbondioksit örnekleme işlemlerini gerçekleştirmektedir. Gaz analiz cihazı Servomex firmasından tedarik edilmektedir. Gaz analiz cihazına giden gazın şartlandırma sistemi de ünite kapsamındadır. Debi ayarlaması, filtreleme, soğutuculu olarak gazın nemden arındırılması gibi işlemler şartlandırma sisteminde gerçekleştirilmektedir.

- Kontrol Kabini:

Deney gazlarının belirlenen debi miktar ve hassasiyetinde sağlanması için kütlesel debimetre (Mass Flow Controller) cihazlarını barındırmaktadır. Kontrol kabini, ayrıca tüm cihaza ait otomasyon sistemini ve kontrol bilgisayarını barındırmaktadır. Bek yakma/söndürme, gaz debi değeri, tüm ölçümler ve deney ile ilgili tüm hesaplamalar ve raporlama işlemlerini gerçekleştirmektedir. Kolay kullanımlı deney yazılımı, minimal kontrol ve bilgi girişi ile tüm deney sürecinin, standarda uygun biçimde, otomatik olarak gerçekleştirilmesini sağlar.