- Dünyada oluşan çevre bilincine paralel olarak geliştirilen, metallerin ve toz boya materyalinin bir manyetik ortam içerisinde farklı elektrikle yüklenmeleri, bunun sonucunda toz materyalin mıknatıs etkisiyle metal yüzeyi kaplaması esasına dayanan bir boyama yöntemi olarak ortaya çıkmıştır. Toz boya kaplanan metal yüzey 180-200 derece yüksek ısı ile fırınlanarak boyanın kürlenmesi sağlanmakta ve böylece metalin bir parçası haline gelen boyalı bir yüzey elde edilmektedir.

-Günümüzün yegane çevreci bir ürünü olan elektrostatik toz boya, uygulama esnasında kullanılan boya miktarının %98'nin metale tutturulabildiği sonucu ile bunu kanıtlamaktadır. Püskürtme esnasında boya zerreciklerini çok düşük 07 mA ve çok düşük doğru akım yükleyerek topraklanmış parçanın üzerine transferidir.Sistemde diğer elektrikli el aletlerindeki gibi (matkap motoru vs.) cereyan çarpma ihtimali yoktur.Boya tanbancadan çıkarken (-) elektrik yüklenir. Boyanavak topraklanmış parçanın yüzeyine çengel şeklinde kuvvet yollarını takip ederek gider.

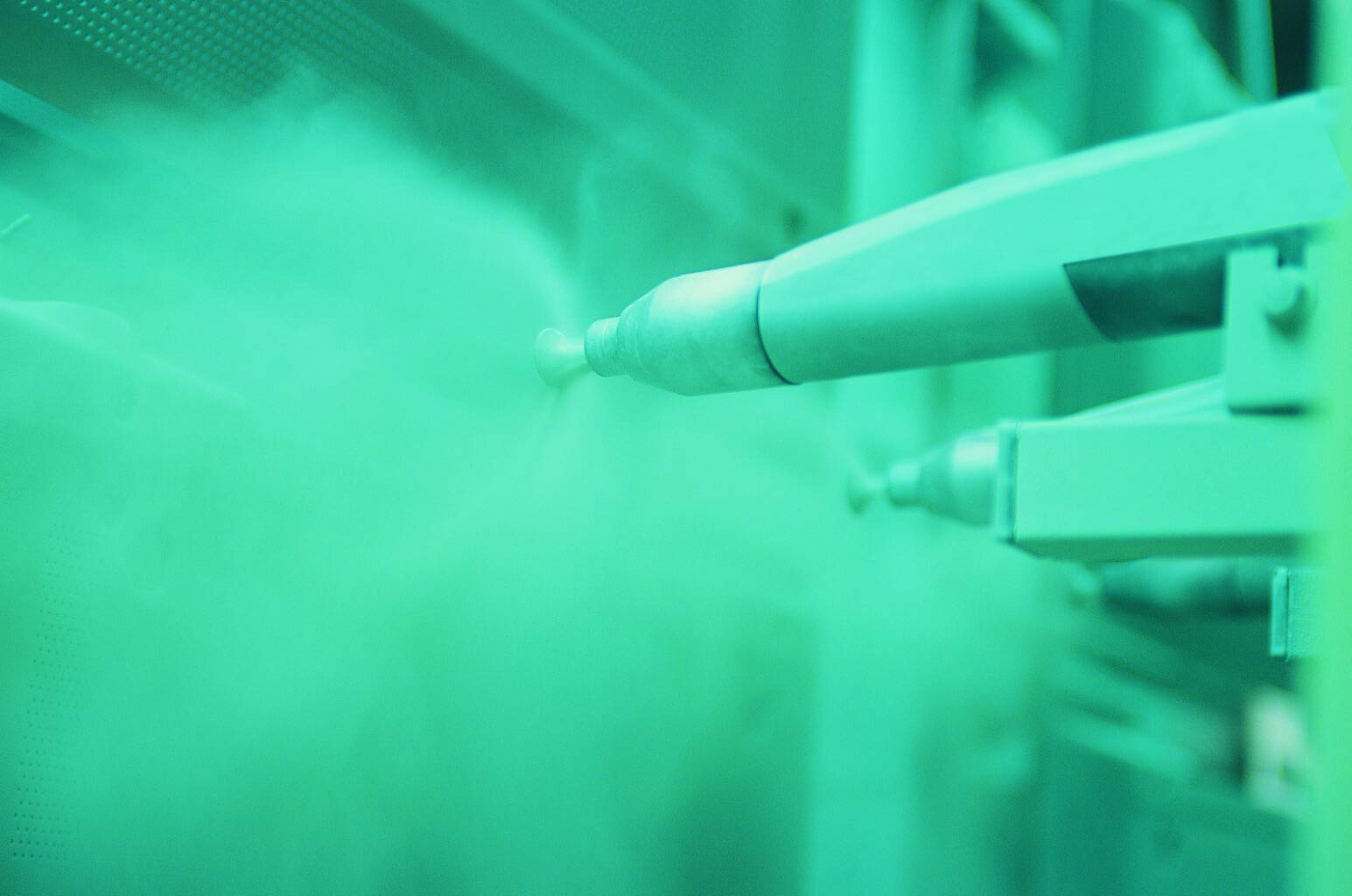

-Boya zerrecikleri; zıt kutuplar birbirini çeker prensiplerine göre parça üzerine çekilirler. Ancak kendi aralarında aynı kutupta olduklarından birbirlerini iterek homojen dağılımı sağlarlar.Böylece akıntı ve damlama ihtimalini yok denecek düzeye indirirler. Polymer tozlarının elektrostataik olarak kaplanacak parçaların üzerine ayrıştırıldıktan sonra eritilmesi ile meydna gelen kaplamaya toz boya kaplama denir. Elektrostatik toz boyama solvent içermeyen bir yüzey kaplama metodudur. Kaplayıcı malzeme, son kat boya tabakasını oluşturan çok ince toz boya partikülleridir. Toz boya, boya kabininde özel boya tabancaları vasıtasıyla atılır.

- Tabancadan geçerken elektrostatik yüklenen toz boya partikülleri kabin içinde boyanacak malzemeye yapışır ve kaplama işlemi gerçekleşmiş olur. Toz boyanın malzeme yüzeyine tam olarak yapışabilmesi için malzemenin de çok iyi bir şekilde topraklanması gerekir. Fazla atılan boya, kabinde bulunan boya geri kazanım sistemi sayesinde toplanır ve tekrar kullanıma sokulur. Boya geri kazanım sistemi elektrostatik toz boyama teknolojisinin en büyük ekonomik avantajlarından biridir. Malzeme toz boya ile kaplandıktan sonra pişirme fırınına girer. 200ºC olan fırın ısısı toz boyanın erimesini ve malzeme üzerine yapışmasını sağlar. Sonuçta çok dayanıklı, ekonomik, çevre dostu, geniş renk yelpazeli ve parlak bir yüzey kaplaması elde edilir.

- Solvent içermemesi, yüzey kalitesi, dayanıklılığı, boya geri kazanım sistemi, ekonomikliği ve çevre duyarlılığı elektrostatik toz boyamayı geleneksel boyama işlemlerine göre daha çekici bir alternatif yapmaktadır.

- Alüminyum ve çelik parçalar üzerinde uygulanan toz boyama teknolojisinin son yıllardaki sürekli gelişimi endüstriyel yüzey kaplama alanında önemli bir atılımın gerçekleşmesini sağlamıştır. Bir çok ihtiyaca kolaylıkla çözüm sağlayan toz boyama teknolojisinin kaplama, dış görünüş, kalite, dayanıklılık, ekonomi ve çevre korunumu gibi geleneksel boyalara göre sayısız avantajları vardır.