Özdekan genleşme derzleri su geçirmez olup üst yapının hareket kabiliyetini sağlar. Bu derzler elastomer elemanlarından üretilip, doğru montaj şekilleri ile üst yapıya monte edilir.

İçerisinde bulunan çelik takviyeli plakalar elastomere komple vulkanize edilir. Bu proses tamamıyla paslanmaya karşı koruma sağlar ve genleşme derzinin

kullanım ömrünü uzatır.

Elastomer formülasyonu yağ, petrol, tuz, taş, kar ve zararlı güneş ışınlarından vb. dış etkenlerden etkilenmeyecek şekilde üretilmektedir.

Tüm genleşme derzleri kauçuğun kayma deformasyon özelliği sayesinde yapının deformasyon ve hareketine uyum sağlar (hareketler değişik açılarda 0°den 90°ye kadar değişiklik gösterebilir).

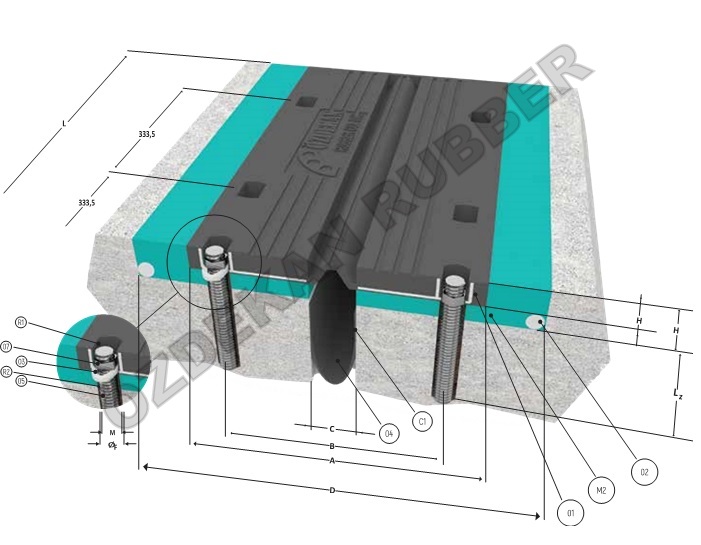

Ankraj civataları özel antipas koruyucu kaplamalı olup tüm elastük yük reaksiyonlarını ve diğer yükleri absorbe ederler.

Bunlara ekstra olarak genleşme derzlerinin düşey yönde hareket kabiliyetini sağlarlar. Bu özellik tüm durumlar için önemlidir.

Çünkü farklı yük ve hareket durumları farklı düşey deplasman hareketlerine yol açabilir. 2006 yılından beri Özdekan’ın üretmekte olduğu genleşme derzlerinin en önemli avantajları aşağıdaki gibidir.

Avantajları

- Elastomer ve çeliğin birbirine vulkanize edilmesi ile basir tasarımlar yapılabilmesi

- Genleşme derzinin et kalınlığının küçük olması

- Çelik veya betonarme köprülerde montaj kolaylığı sağlaması

- Bakım, onarım be değişikliğinin kolay olması

- Araç hareketlerine mukavim olması

Bu genleşme derzleri değişik ölçülerde üretilip, birbirine ek yapılarak kimyasal dübeller yardımı ile monte edilebilir.

Genleşme derzlerinin sabitleme işlemi ankrajlar yardımı ile yapılır, somunlar sıkıldıktan sonra genleşme derzinin hareketlere karşı mukavemeti sağlanır.

Böylece yapıda oluşan yatay yğkler (frenleme etkilerinden dolayı, büzülme etkisinden dolayı, sıcaklık değişikliklerinden dolayı) kauçuk ve betonun sürtünmesi ile altyapıya aktarılır.

Bu genleşme derzleri çelik yapılara da monte edilebilir. Daha yüksek hareket kapasitesine sahip genleşme derzleri dört adet paralel oluk kullanılarak sağlanır ve bu oluklar sayesinde genleşme derzinin iç kısmına doğru hareketinde genleşme derzinin yukarı doğru kalkması engellenir.

Doğru bağlantı yöntemi kullanılarak bu genlşeme derzleri yapı ile birlikte istenilen hareketi sağlar