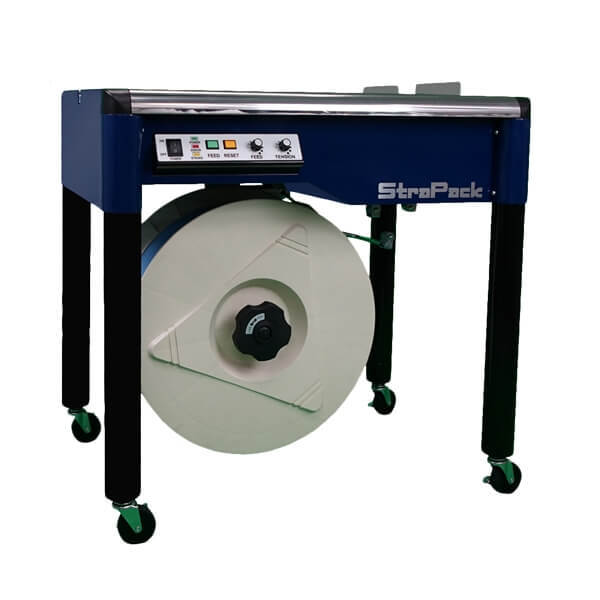

Strapack IQ-400 Yeni Nesil Çember Makinası

Kullanım alanının zengin olması nedeniyle en çok kullanılan Strapack IQ400 Çember Makinasıdır ve Tercih Edilen çember Makinası’dır Ebat Sınırlaması Olmaksızın, Makine Üzerine Konulan Tüm Ürünler Çemberlenebilir. Ürün Makine Üzerine Konulduktan Sonra, Hazır Durumda Olan Çember, Ürün üzerinden dolaştırılmak suretiyle çemberleme kanalına değdirildiği anda, makine otomatik olarak germe ve kaynatma işlemlerini yaparak, çemberleme işlemini tamamlar. Ekonomik, kolay ve hızlı çemberleme için ideal bir makinedir.

Koli kutu Bağlama, oluklu karton Bağlama, gazete dergi paketleme, sebze meyve narenciye paketleme , hortum, kablo,Kiremit, gibi bir çok ürünlerin bağlanmasında kullanılır. Kullanım alanının zengin olması nedeniyle en çok kullanılan çember makinası’dır. Bağlanacak ürünlerin ağırlığına Göre 5mm İthal Çember, 8mm Ambalaj Çemberi,12mm Polipropilen Çember,16mm Plastik Çember Aralığında Kullanılabilir

Strapack IQ-400

Yenilikçi Strapack’ın En Son ve En Modern Yarı Otomatik Çember makinesıdır.

Adet DC Motor ; ile Hem Sessiz ,Daha Sağlam

Motorlardan Direk Güç ; Kayış Sistemi ve zincir Sistemi Olmadığı içi Direk Motorlardan Güç Alarak Daha Hızlı , Arıza Olanağı Minumun, ve %75’e Yakın Tüketim Tasarruf Sunar

Az Hareketli Parça ; ile Arıza Verme Olanağı Çok Düşüktür. Daha Az Parça Olduğu için Kullanan Müşterilerimiz Arıza Durumunda Çok Basit Ve Hızlı Bir Biçimde Müdahale Şansı Yapılan İşin Durmaması Ve Servis Çağırarak Ek Bir Maliyet ve Diğer makinelara Kıyasla Aynı Zamanda Yedek Parça Gerekmediği İçin Tasarruf Sağlar Çember Özelliği ; Ek Parça Kullanılmadan 05*040 mm İle 15*080 Arası Çember Kullanmak Mümkündür.

Sessiz DC MotorlarıSayasinde Ofis İçi Kullanım İçin İdeal Bir makinedir.

Daha Az Hareketli Parça ; ile Arıza Verme Olanağı Çok Düşüktür. Daha Az Parça Olduğu için Kullanan Müşterilerimiz Arıza Durumunda Çok Basit Ve Hızlı Bir Biçimde Müdahale Şansı Yapılan İşin Durmaması Ve Servis Çağırarak Ek Bir Maliyet ve Diğer makinelara Kıyasla Aynı Zamanda Yedek Parça Gerekmediği İçin Tasarruf Sağlar Çember Özelliği ; Ek Parça Kullanılmadan 05*040 mm İle 15*080 Arası Çember Kullanmak Mümkündür.

Çember Tasarrufu ; Diğer makinelara Kıyasla Özellikle 5 mm Çember Kullanılması Durumunda %40 Yakın Çember Maliyetlerinden Tasarruf ve Yapıştırmadaki Üstün Performansı İle % 5 Yakın Tüm Çemberlerde Tasarruf

Çember Kanal Ayarı ; 3 Adet Hassas Çember Kanal Ayarı İle 5 mm Çemberde Dahi Çemberlerin Üst Üste Yapışması

Elektronik Germe Kontrolü ; İle Daha Hassas İstediğiniz Sıkılıkta Germe Çemberleme İşlemi

Hız Ayarı ; İle İstediğiniz Hızda Çalışma İmkanı

Çemberleme Hızı ; Yaklaşık Olarak 1,5 Saniye İle Çok Hızlı makinedır.

Koruma Sigortası ; İle Daha Hassas İstediğiniz Sıkılıkta Germe Çemberleme İşlemi

Kullanma Klavuzu

Çember Makinası Üzerinde Bulunan Çember Takma Talimatına Uygun Olarak P.p Çember Takılır

Üst Resimde de Görüldüğü Gibi İlk Önce Plastik Kasnak Sökülerek Plastik Ambalaj Çemberi Takılır Daha Sonra Frenleme Sistemlerinden Geçirilerek Çember Aşağıdaki Butonlar Yardımı İle Hazır Duruma Getirirlir

- Numaralı Düğme İle Açma Ve Kapama İşlemi Yapılır

- Nolu Tuşa Basarak Resetleme veya Çemberi İleri Verebilirsiniz

- Nolu Buton İle Hazır Durumda Olan Çemberi Ürün veya Koli Ebatına Uygun Olarak Çember Uazatılanbilir

- Feed Düğmesi Çember Metrajını Ayarlamak İçin Artırılabilir

- Tension Düğmesi Koli veya Ürünün Yeteri Kadar Sıkmak İçin 5-45 Kğ arası Ayarlama İçin Kullanılır

Makine Üzerine Konulan Tüm Ürünler Çemberlenebilir. Ürün Makine Üzerine Konulduktan Sonra, Hazır Durumda Olan Çember, Ürün üzerinden dolaştırılmak suretiyle çemberleme kanalına değdirildiği anda,makine otomatik olarak germe ve kaynatma işlemlerini yaparak, çemberleme işlemini tamamlar. Ekonomik, kolay ve hızlı çemberleme için ideal bir makinedir.

ÇEMBER MAKİNASI GENEL TEMİZLİK PERİYODİK BAKIM VE ARIZA KONTROLLERİ

Her Bir Oparatör Kullanmakta Olduğu Çember Makinesi Bakım Onarım ve İş güvenliğinden Sorumludur

Çemberleme Makinası Arıza Onarımı veya Periyodik bakıma başlamadan önce elektrik bağlantısını kes

Bakımı yapılacak/arızalı kısımlarını gözle kontrol et. Kırılma, deformasyon, yağ sızıntısı, veya benzeri anormal bir görünüm olup olmadığını kontrol et

Makinanın etrafını ve müdahale edilecek kısımlarını yağ, kir veya pislik kalmayacak şekilde iyice temizle.

Sökülmesi gereken yerler varsa sökülecek kısımların etrafını iyice temizle ve bakım da gerekli olacak

alet ve cihazları hazırla.

Bakımı yapılacak/arızalı kısmı sök. Açılan yerlerin yağı kalmayacak şekilde temizliğini yap.

Temizlendikten sonra kırık, çatlak, yağ sızıntısı, deformasyon vb. anormallikler olup olmadığını ve parçalarda boşluk olup olmadığını kontrol et.

Bağlantı yerlerinde gevşeme veya kopma olup olmadığını kontrol et.Tüm Vida ve somun Vb.

Çember Makinası Tamir veya bakımın yapamayacağın bir durumla veya anlamadığın bir durumla karşılaşırsan Çember Makinası Yetkili Teknik Servisi Haber ver.

TÜM YEDEK PARÇALARI STOKLARIMIZDA MEVCUTTUR.

Tüm Bakım Kontrolleri ve arıza Onarımında Balata spreyi Kullanılması Önerilir.

Yetkili Servisten Ücret Karşılığı Temin Edebilirsiniz.

1) Günlük Bakımlar

- Hergün İş Bitiminde Hava İle Temizlenmesi

- Gözle görülebilen kısımlarda kırılma, aşınma ve yıpranma olup olmadığını kontrol et.

- Varsa dişli, rulman ve kasnak gibi hareketli parçalarda Kırılmış, aşınmış, boşluk olup olmadığını kontrol et.

2) Haftalık ve Aylık Bakımlar

- Hava ile temizlenmesi

- Hergün İş Bitiminde Hava İle Temizlenmesi

- Gözle görülebilen kısımlarda kırılma, aşınma ve yıpranma olup olmadığını kontrol et.

- Varsa dişli, rulman ve kasnak yay gibi hareketli parçalarda Kırılmış, aşınmış, boşluk olup olmadığını kontrol et.

- Makinanın etrafını ve İç kısımlarını yağ, kir veya pislik kalmayacak şekilde iyice temizle.

- Temiz bez ve balata spreyi yardımı ile , makinanın içi , çember kanalları temizlenmesi

- Özellikle Rezizstans Yay Kontrolü Rezizstasın Altını ve Üstünün Temizlenmesi

3) Aylık Bakımlar

- Hava ile temizlenmesi

- Hergün İş Bitiminde Hava İle Temizlenmesi

- Gözle görülebilen kısımlarda kırılma, aşınma ve yıpranma olup olmadığını kontrol et.

- Varsa dişli, rulman ve kasnak yay gibi hareketli parçalarda Kırılmış, aşınmış, boşluk olup olmadığını kontrol et.

- Makinanın etrafını ve İç kısımlarını yağ, kir veya pislik kalmayacak şekilde iyice temizle.

- Temiz bez ve balata spreyi yardımı ile , makinanın içi , çember kanalları temizlenmesi

- Rediktör’e yağ eklenmesi

- Elektrik Kablo , Rezistans,sigorta ,Kontrollerinin Yapıılması

4) Yıllık Bakımlar

- Çember Makinası Yetkili Teknik Servis Tarafından Yapılması Önerilir.