Titreşime Dayanıklı Elek GövdesiMS ve MGS serisi eleklerin tümü titreşime dayanıklı, yüksek gerilimli ısıl işlem görmüş yan sac ile üretilmiştir. Bu da müşterilerimizin, uzun vadede ilk günkü sağlamlığı ile eğimli elekleri kullanmalarını sağlamaktadır. Çelik sacın dayanıklılığı sayesinde eleğin gövdesi titreşime karşı daha dayanıklı hale gelmektedir.

Özel gövde sacı sayesinde diğer eleklerin özellikle tahrik sisteminin çevresinde oluşan ve zamanla büyüyerek elekleri kullanılmaz hale getiren mikro çatlaklar MEKA eğimli eleklerde oluşmamaktadır.

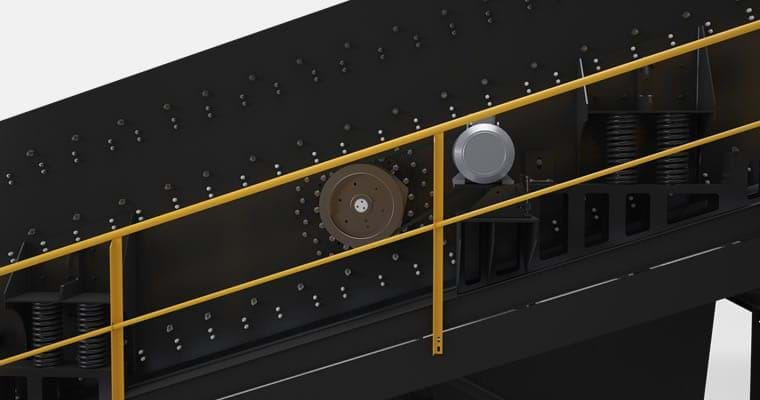

Kendinden Gergili Motor SehpasıMotor ve motor kayışlarını titreşimlerin yaratabileceği gerginliklerden korumak ve bu sayede bakım zaman ve giderleri kısaltmak için kendinden gergili titreşimli motor sehpası MS ve MGS serisi eleklerde standart olarak kullanılmaktadır.

Tümüyle Huck-Bolt Bağlantılı GövdeGeleneksel cıvata ve somunla ile birleştirilen elek gövdeleri titreşimden dolayı meydana gelen gevşemeler, cıvata kesmeler, çalışma verimi düşürürken iş güvenliği açısından önemli riskler oluşturur. MEKA MS ve MGS serisi eleklerde Huck-Bolt kilitli cıvata sistemi kullanılarak cıvata bakım gereksinimi ortadan kaldırılırken güvenli çalışma ortamı sağlanmaktadır. Türkiye’deki üreticiler arasında standart olarak Huck-Bolt elek gövdesine sahip tek üretici Meka’dır.

Raylı Oluk Sistemi İle Bakım ve İşletme KolaylığıElek telleri kullanılan malzemeye bağlı olmakla birlikte, eleklerde en çok değişen sarf malzemelerindendir. Bu kaçınılmaz bakım durumunu hızlı ve kolay hale getirmek için 8 m² ve üstü eleklerimizde ön oluğu raylı olarak tasarladık. Herhangi bir kaldırma aracına gereksinim olmadan raylı sistemde ön oluğu iterek açıp ve gerekli bakımlara ve kontrollere birkaç dakika içinde başlanabilmektedir.

Modüler Tip Tahrik SistemiMEKA MS ve MGS serisi eleklerde servis sürecinde kolaylık sağlaması için modüler tip tahrik mekanizması kullanılmaktadır. Ayrı ayrı ve kolaylıkla sökülebilen tahrikler bakım süresi de önemli ölçüde azaltmaktadır. Ayrıca modüler tahrikleri birbirine bağlayan kardan şaft, eski tip ve tek parça hantal şaftlara göre hem ağırlık avantajı sağlamakta hemde bakım kolaylığına katkıda bulunmaktadır.

TEKNİK ÖZELLİKLER

Aşağıda teknik ayrıntıları verilen eğimli eleklerimizi inceleyin. Daha detaylı bilgi alabilmek veya özel ihtiyaçlarınıza yönelik çözüm talepleriniz için lütfen bizimle iletişime geçin. Mühendislerimiz, projenize destek olmaktan memnuniyet duyacaktır.

EĞİMLİ ELEKLER TEKNİK ÖZELLİKLER

| Ölçüler |

1200x4000(mm) |

1500x4000(mm) |

1600x5000(mm) |

2000x5000(mm) |

2000x6000(mm) |

2400x6000(mm) |

2500x6300(mm) |

| Kat Sayıyı |

2/3/4 |

2/3/4 |

2/3/4 |

2/3/4 |

2/3/4 |

2/3/4 |

2/3/4 |

| Power |

7.5(kW) |

15(kW) |

15(kW) |

18.5(kW/rpm) |

22(kW/rpm) |

30(kW) |

37(kW |