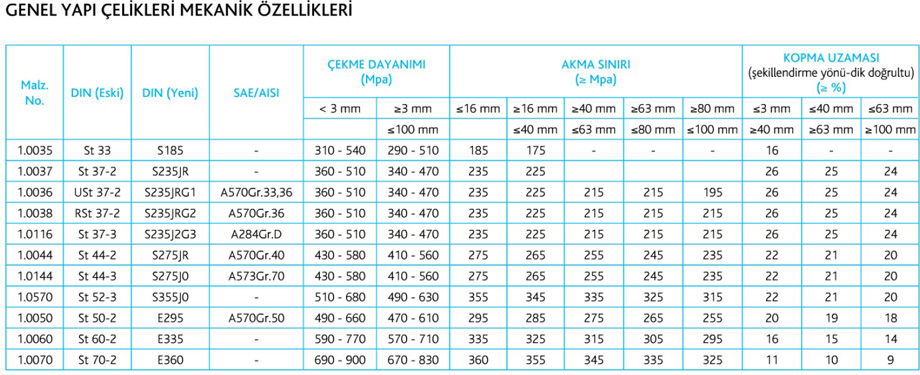

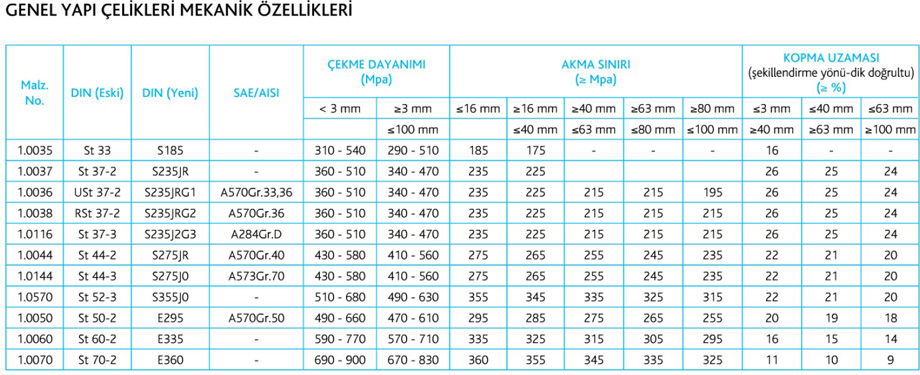

Çekme dayanımına göre ifade edilen yapı çelikleri, öncelikli olarak çekme gerilmeleri ve akma sınırı değerleri dikkate alınan, çelik konstrüksiyon, köprü yapımı, basınçlı kap ve donanımları, taşıt imalatı ve makine konstrüksiyonlarında kullanılmak üzere tercih edilir.

Bu çelikler genellikle alaşımsız çelik olarak tanımlanır, mekanik özellikler daha çok karbon miktarına bağımlıdır fakat başta azot ve fosfor olmak üzere, üretim hammaddelerinden ve üretim şekillerinden kaynaklanan mangan, silisyum, bakır ve kükürt elementleri de oldukça etkilidir.

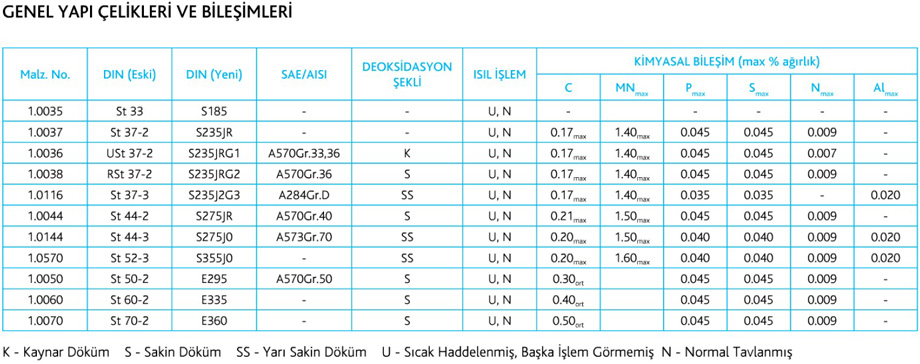

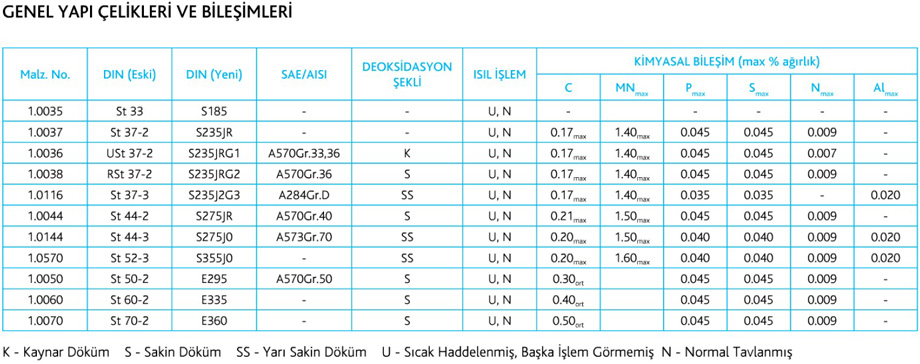

Genel yapı çelikleri kalite gruplarına göre sınıflandırılırlar. Standartlarda yapılan yeni düzenlemeler sonucunda;

• 1. kalite grubuna yalnızca St 33 çeliği verilmektedir. St 33 çeliğinde kimyasal analiz değerleri verilmez, üretim yöntemi ve döküm tarzı serbest bırakılmıştır. Denilebilir ki; 1. kalite grubundaki çelikler itinalı şekilde ergitilmezler.

• 2. kalite grubundaki çelikler, en fazla %0,050 P ve %0,050 S içerirler ve daha çok kaynak konstrüksiyonlarında tercih edilirler. Silisyum ve mangan miktarı da belirlenmiştir. Fe 37 çeliği kaynar*, sakin dökülmüş** veya yarı sakin dökülmüş*** olarak dökülebilir. Fe 44, Fe 50, Fe 60 ve Fe 70 çelikleri mutlaka sakin ya da yarı sakin dökülürler.

• 3. kalite grubundaki çelikler yaşlanmaya**** dayanıklı ve ince taneli çelik olarak, özellikle sakinleştirilerek dökülürler. Fosfor ve kükürt miktarları %0,04O ile sınırlandırılmıştır. Genellikle 0,020 Al ile deokside edilirler.

Genel yapı çeliklerinin talaşlı şekillendirilmesinde, ağırlıklı olarak daha çok normal tavlı veya soğuk şekillendirilmiş malzeme tercih edilmelidir. Normal tavlama ve yaklaşık 600-650 °C sıcaklığında uygulanan gerilim giderme tavlamasının dışında, genel yapı çeliklerine ısıl işlem uygulanmaz. Bunun nedeni, yapı içerisinde istenmeyen elementlerin fazla oluşu; bunun neticesinde oluşan kuvvetli çökelmeler ve sertleştirme çatlaklarıdır.

Genel yapı çelikleri, nokta ve makara dikiş kaynağı ile birlikte, direnç kaynağına da uygundur. Fe 60 ve Fe 70 çelikleri, kaynaktan sonra yavaş soğutulmalı veya derhal tavlanmalıdır. Eğer çeliklerdeki karbon miktarı %0,2′den az ise diğer pres kaynağı yöntemleri de kullanılabilir.

* Kaynar dökülmüş çelik, erimiş çelikte bulunan demir oksidin çeliğin kalıpta katılaşması sırasında içindeki karbonun bir kısmı ile birleşip, karbon monoksit teşkil ederek dokusunda gaz habbecikleri etkisi österen ve enellikle üze inde ince bir ferrit tabakası bulunan çeliktir.

** Sakin dökülmüş çelik, kepçede veya kalıpta oksijen bağlayıcı (deoksidan) madde kullanılarak erimiş çelikteki demir oksidin oksijeni tamamen alınmış olan çeliktir. (yapı diğerlerine

oranla homojendir)

*** Yarı sakin dökülmüş çelik kepçede ve kalıpta, deoksidan madde kullanılarak erimiş çelikte bulunan demir oksidin oksijeni kısmen alınmış olan çeliktir.

**** Yaşlanmayan çelik, uzun süre bekledikten sonra vurma dayanımı, imal edildiği durumdakine göre çok az değişiklik gösteren çeliktir.