Islah çeliklerinde sertleşebilirlik özelliklerinin yanında, yüksek dayanım ve süneklik de istenir. Yeterli seviyede sertlik elde edilebilmesi için, ıslah çelikleri diğerlerine nispeten yüksek karbon içerirler. Kalın kesitli parçalar için sertlik derinliğinin en önemli kriter olması sebebiyle, bu parçalar alaşımlı ıslah çeliklerinden imal edilirler.

Islah çeliklerinin seçiminde, parça boyutları ve dayanım değerleri ön plandadır. Alaşımsız ıslah çelikleri ancak küçük kesitli parçalarda verimli olabilir. Kalın kesitli parçalar için, sertlik dağılımının homojen olması, çeliğin alaşımlı olmasına bağlıdır. Sertlik dağılımının, malzeme alaşımlarına göre değişimleri Jominy testi sonuçları ile gözlenebilir. Jominy testi basit bir ifade ile; sertleştirme sıcaklığına kadar ısıtılan çubuk şeklinde bir malzemenin sadece bir ucundan soğutulmasıyla soğutulan uca olan mesafelerdeki sertleşme değerlerini ifade eden Islah çelikleri alevle ve indüksiyonla sertleştirilebileceği gibi, ıslah edildikten sonra da alev ve indüksiyonla sertleştirilebilirler. Bu şekilde ısıl işlem görecek malzemenin seçiminde, kimyasal bileşimin yanı sıra, yüzeyde elde edilecek sertlik değeri ve sertleşme derinliği göz önünde bulundurulur. Alaşımsız çeliklerde sertlik derinliği 3-4 mm olabilirken, alaşımlı çeliklerde bu derinlik 10-12 mm’yi bulur.

Ayrıca indüksiyonla sertleştirme esnasında yüksek mangan çatlama tehlikesi yaratacağından, yüksek karbonlu-düşük manganlı Cf kalite çeliklerin kullanılması daha uygundur. Ayrıca çatlama tehlikesinin azalması, malzeme tane yapısının küçük olmasıyla yakından ilişkilidir.

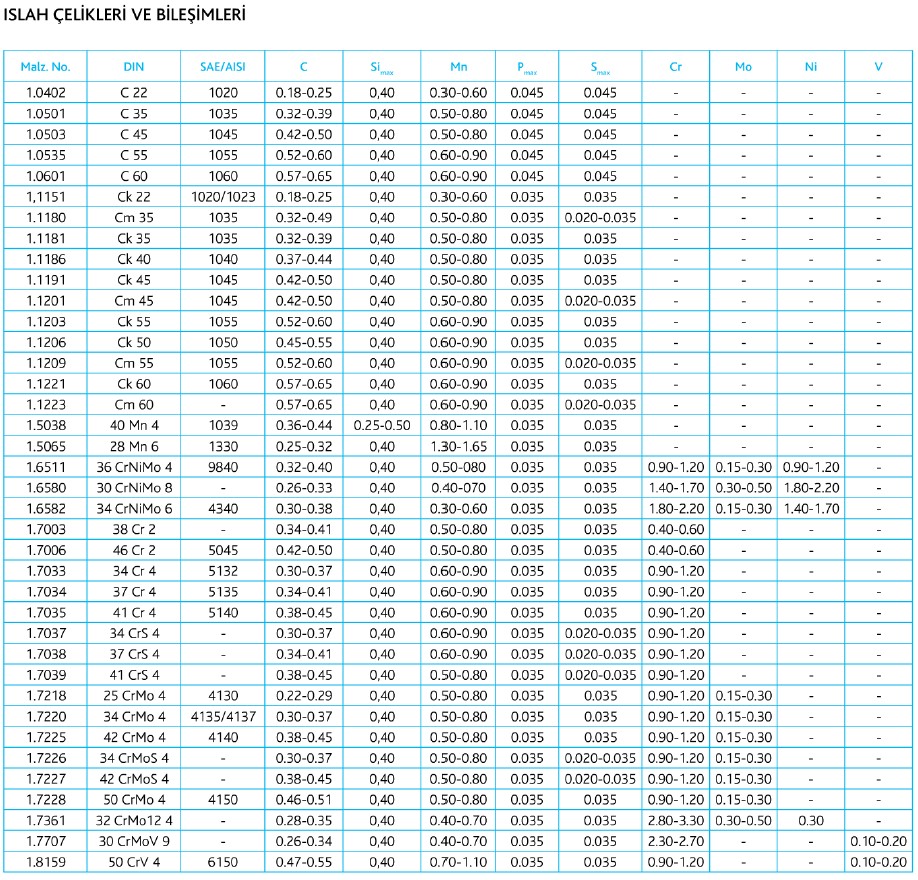

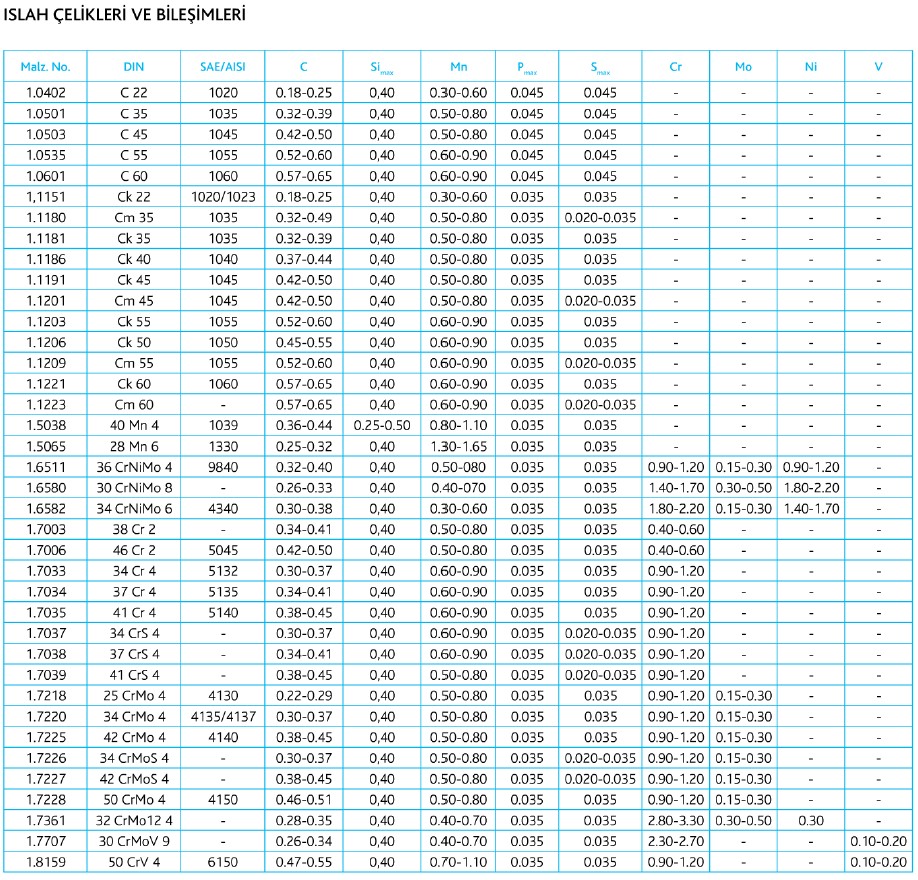

Islah çelikleri kimyasal bileşimlerine göre 4 ana grupta toplanır.

1. Alaşımsız ıslah çelikleri

2. Mangan alaşımlı ıslah çelikleri

3. Krom alaşımlı ıslah çelikleri

4. Krom-molibden alaşımlı ıslah çelikleri

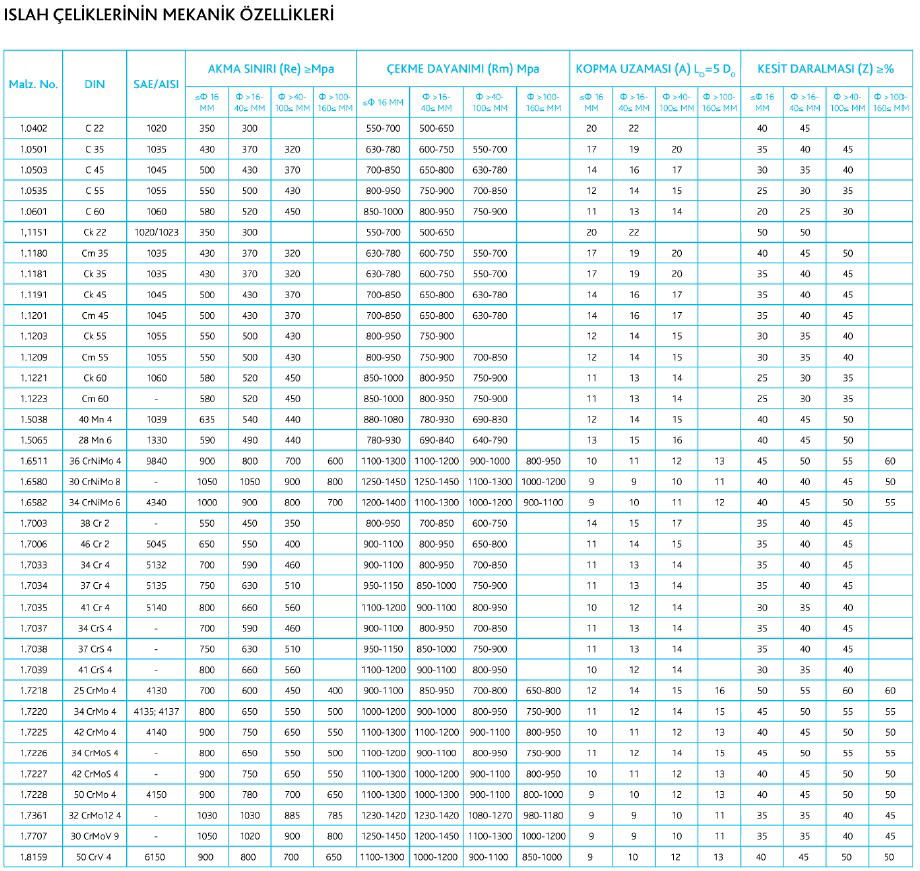

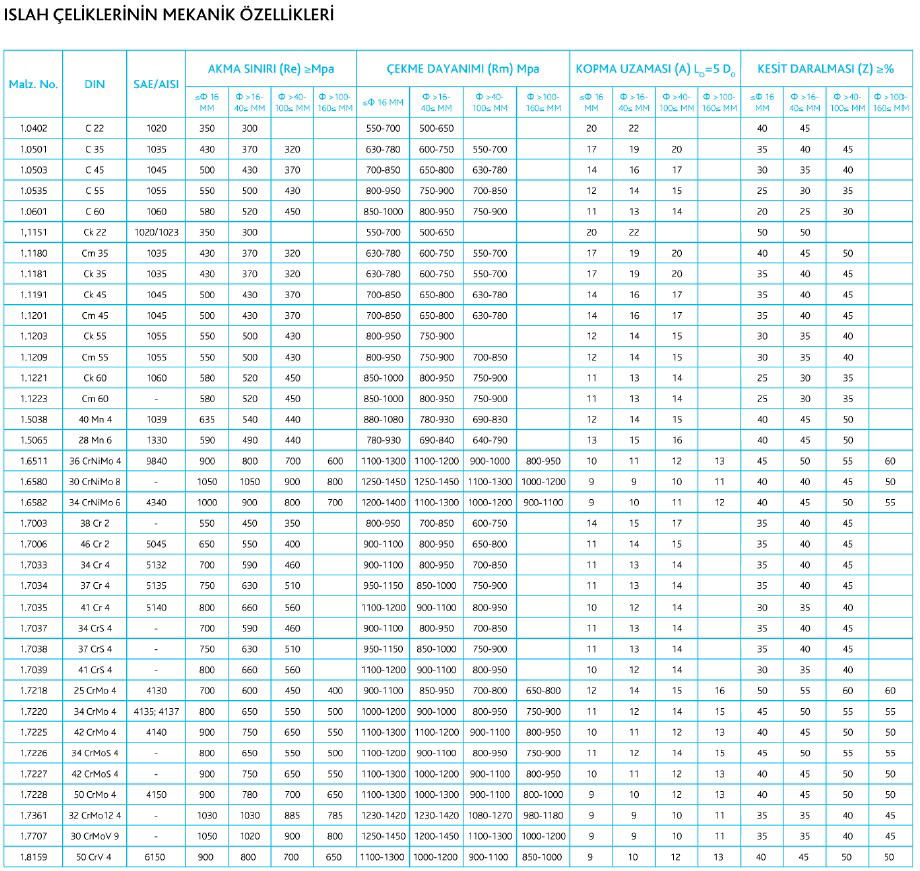

Alaşımsız çeliklerde, ıslah dayanımı karbon miktarıyla artmaktadır. 16 mm çapa kadar en düşük akma sınırı 370 N/mmz (%C:0,25) ila 570 N/mm* (%C:0,50) arasındadır. 16-40 mm çap arasındaki boyutlarda 50-80 N/mm2 daha düşük olur.

Mangan alaşımlı ıslah çeliklerinde mangan setreleşebilirliği arttırdığından 30 Mn 4 ve 40 Mn 4 çeliklerinde akma sınırı C60 çeliğindeki özelliklerini gösterir. Krom alaşımlı ıslah çeliklerinde krom elementi sertleşebilirliği oldukça fazla arttırır ve plastisiteye de olumlu etki yapar. Örneğin 40 Cr 4 çeliğinde 16-40 mm çap aralığında minimum akma 700 N/mm2′dir.

Molibden kroma nazaran daha kuvvetli sertleşebilme kabiliyetini artırır. Ayrıca meneviş dayanımını arttırır ve meneviş kırılganlığı ihtimalini azaltır.